The closed end hollow guide rail is a specialized elevator guide rail featuring a rectangular hollow structure with sealed (closed) ends. Designed to meet the demands of cleaner shaft environments and optimized strength-to-weight performance, this rail type is widely used in modern elevator systems requiring both durability and ease of installation.

Unlike standard hollow rails with open ends, the closed-end design prevents dust, moisture, and foreign matter from entering the rail cavity, making it especially suitable for high-precision, dust-sensitive, or long-term maintenance-restricted applications.

Closed-end hollow guide rails are specifically designed to enhance environmental protection and long-term operational reliability in demanding industrial conditions. By sealing the ends of the hollow profile, this design effectively prevents dust, debris, moisture, and other contaminants from entering the internal cavity of the rail. As a result, the risk of internal corrosion, abrasive particle accumulation, and lubricant contamination is significantly reduced, even in high-dust, humid, or chemically aggressive environments.

This enclosed structure contributes directly to improved reliability over the service life of the guiding system. With fewer contaminants affecting internal surfaces and load-bearing zones, wear rates are more consistent, and unexpected performance degradation is minimized. Closed-end hollow guide rails, therefore, require less frequent cleaning and maintenance while maintaining stable linear guidance and dimensional integrity over extended operating periods. These characteristics make them particularly suitable for applications where environmental exposure, uptime requirements, and long-term durability are critical considerations.

According to international standards: ISO7465:2007; ISO630: 2021. According to international standards, conduct comprehensive testing of raw materials based on the material certification provided by suppliers to ensure that the quality of each batch of raw materials meets the requirements.

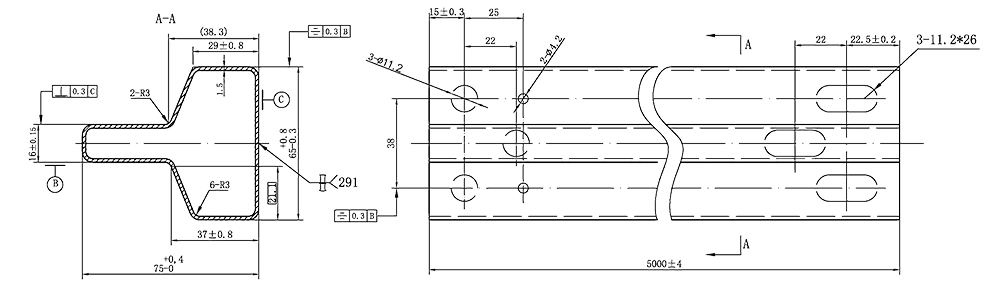

Configure two automated guide rail production lines. The equipment must ensure that the produced items comply with or exceed customer requirements while maintaining the stability of straightness, distortion, and surface roughness

Given the stringent requirements for straightness and twist in BE grade guideways, specialized automatic straightening and twist correction equipment, along with advanced detection systems, have been implemented. The straightness is maintained within 0.5 mm, while the twist is controlled to within 30' per meter

The service concept of "customer first" asserts that, regardless of where our services are delivered—be it within the company, at the client's workplace, on the construction site, or during transportation—our primary objective remains to satisfy the client