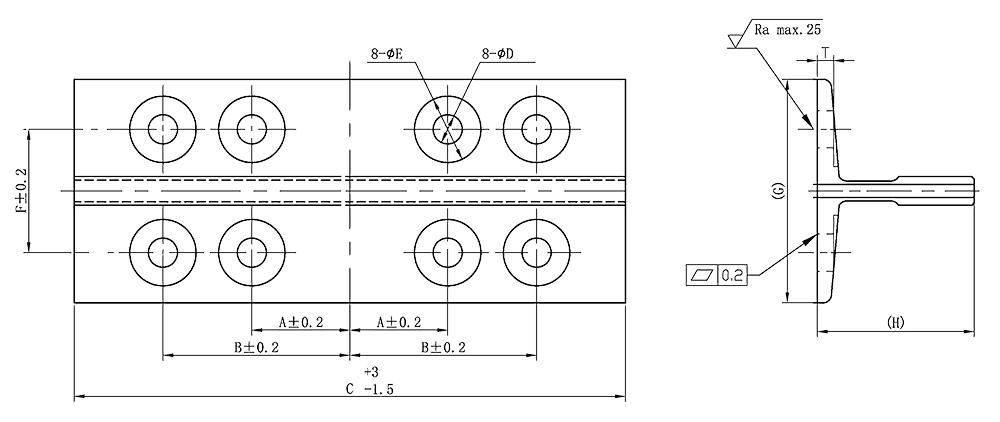

| Model | A | B | C | D | E | F | G | H | T |

| T89 | 38.1 | 114.3 | 305 | 13 | 26 | 57.2 | 89 | 61 | 7 |

| T89-1 | 38.1 | 114.3 | 305 | 13 | 26 | 57.2 | 89 | 61 | 7 |

| T127-1 | 38.1 | 114.3 | 305 | 17 | 33 | 79.4 | 127 | 88 | 7 |

| T127-2 | 38.1 | 114.3 | 305 | 17 | 33 | 79.4 | 127 | 88 | 7 |

T-type solid connecting plates are precision-engineered components designed to securely join two sections of T-type solid elevator guide rails, ensuring accurate alignment, structural continuity, and long-term mechanical stability. Manufactured from high-strength carbon steel or alloy steel, these connecting plates are built to withstand heavy loads and repeated dynamic stresses, making them ideal for passenger and freight elevator systems requiring reliable and durable rail connections.

T-type solid connecting plates are designed to provide robust structural linkage with high rigidity and predictable load-bearing behavior. The T-shaped geometry creates a distinct load path where the vertical web primarily resists bending and shear forces, while the horizontal flange distributes load across a wider area. This configuration improves the overall stiffness of the connection and reduces localized stress concentrations, making it suitable for heavy-duty frameworks and linear guide systems.

Under bending loads, the flange functions as the main bending member, resisting deflection and maintaining alignment between connected components. The web, acting as a shear panel, transfers shear forces effectively and contributes to torsional stability. The solid nature of the plate enhances its ability to withstand repeated dynamic and impact loads, minimizing deformation and ensuring long-term dimensional stability. Compared to hollow or thin-walled connectors, T-type solid plates offer superior fatigue resistance and a higher safety margin, especially in applications involving vibration, shock, or cyclic loading. When properly sized and installed, they provide a reliable, high-performance connection solution for demanding industrial structures.

According to international standards: ISO7465:2007; ISO630: 2021. According to international standards, conduct comprehensive testing of raw materials based on the material certification provided by suppliers to ensure that the quality of each batch of raw materials meets the requirements.

Configure two automated guide rail production lines. The equipment must ensure that the produced items comply with or exceed customer requirements while maintaining the stability of straightness, distortion, and surface roughness

Given the stringent requirements for straightness and twist in BE grade guideways, specialized automatic straightening and twist correction equipment, along with advanced detection systems, have been implemented. The straightness is maintained within 0.5 mm, while the twist is controlled to within 30' per meter

The service concept of "customer first" asserts that, regardless of where our services are delivered—be it within the company, at the client's workplace, on the construction site, or during transportation—our primary objective remains to satisfy the client