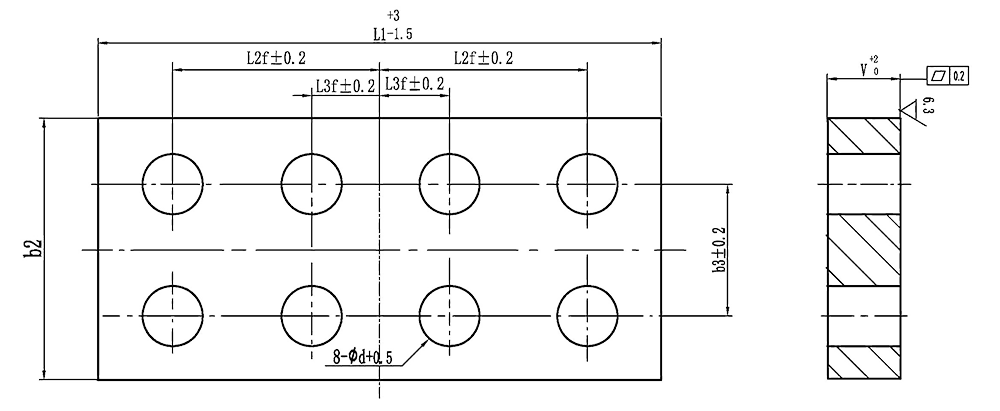

| Model | b2 | v | L1 | b3 | L2f | L3f | d |

| T70-1/B | 70 | 10 | 250 | 42 | 105 | 25 | 13 |

| T75/B | 75 | 10 | 240 | 42 | 150 | 25 | 13 |

| T75-1/B | 75 | 10 | 240 | 43 | 90 | 30 | 13 |

| T75-3/B | 75 | 10 | 240 | 43 | 90 | 30 | 13 |

| T78/B | 75 | 13 | 250 | 42 | 105 | 25 | 13 |

| T82/B | 82 | 8.5 | 216 | 50.8 | 81 | 27 | 13 |

| T82-3/B | 82 | 13 | 305 | 50 | 114.3 | 38.1 | 13 |

| T89/B | 90 | 13 | 305 | 57.2 | 114.3 | 38.1 | 13 |

| T89-1/B | 90 | 13 | 305 | 57.2 | 114.3 | 38.1 | 13 |

| T89-2/B | 90 | 13 | 305 | 57.2 | 114.3 | 38.1 | 13 |

| T90/B | 90 | 13 | 305 | 57.2 | 114.3 | 38.1 | 13 |

| T114/B | 114 | 18 | 305 | 70 | 114.3 | 38.1 | 17 |

| T127-1/B | 127 | 17 | 305 | 79.4 | 114.3 | 38.1 | 17 |

| T127-2/B | 127 | 17 | 305 | 79.4 | 114.3 | 38.1 | 17 |

| T140-1/B | 140 | 25 | 380 | 92.1 | 152.4 | 38.1 | 21 |

T89 elevator fish plates are precision-engineered joint components designed to securely connect two T89 elevator guide rail sections, ensuring accurate alignment, reliable load transfer, and safe vertical operation of elevator cars and counterweights. Manufactured from high-strength metal materials, these fish plates provide excellent mechanical stability and are fully compatible with T89 guide rail profiles used in passenger and freight elevator systems.

T89 elevator fish plates play a critical role in maintaining the structural integrity and safe operation of elevator guide systems. As a connection and reinforcement component, they must meet stringent safety and reliability requirements to ensure stable load transfer and prevent catastrophic failure in service. The primary safety consideration is the prevention of loosening, deformation, or fracture under repeated loading, as these failures could compromise guide rail alignment and elevator performance.

To achieve high reliability, fish plates must be designed with sufficient redundancy and safety margin. This includes providing adequate thickness, appropriate fillet radii, and reinforcement features such as ribs or gussets to reduce stress concentration. Bolted connections require precise hole positioning and correct preloading torque to prevent loosening due to vibration and dynamic forces. In addition, corrosion resistance is essential, especially in humid or corrosive environments, to prevent strength degradation over time. Regular inspection and maintenance are also critical, including checking for signs of fatigue cracks, bolt loosening, and corrosion. When designed and maintained correctly, T89 elevator fish plates provide a dependable connection solution that supports long-term elevator safety and operational stability.

According to international standards: ISO7465:2007; ISO630: 2021. According to international standards, conduct comprehensive testing of raw materials based on the material certification provided by suppliers to ensure that the quality of each batch of raw materials meets the requirements.

Configure two automated guide rail production lines. The equipment must ensure that the produced items comply with or exceed customer requirements while maintaining the stability of straightness, distortion, and surface roughness

Given the stringent requirements for straightness and twist in BE grade guideways, specialized automatic straightening and twist correction equipment, along with advanced detection systems, have been implemented. The straightness is maintained within 0.5 mm, while the twist is controlled to within 30' per meter

The service concept of "customer first" asserts that, regardless of where our services are delivered—be it within the company, at the client's workplace, on the construction site, or during transportation—our primary objective remains to satisfy the client