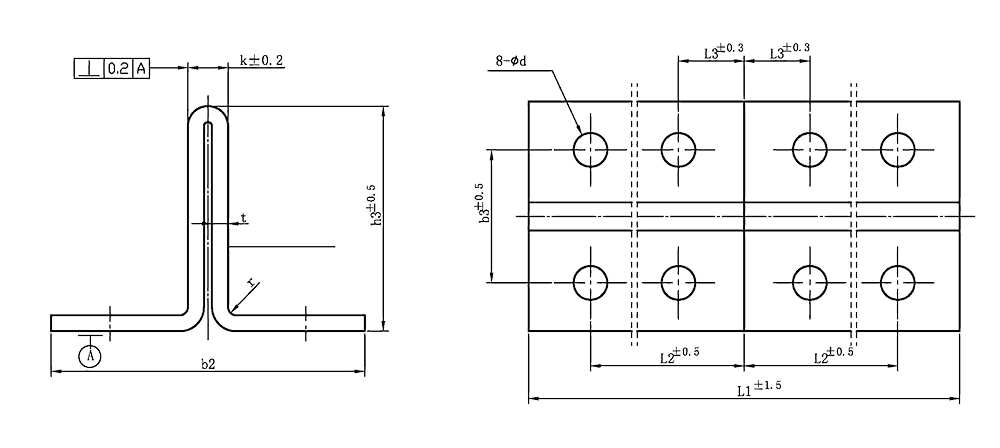

| Model | b2 | h3 | k | t | b3 | r | d | L1 | L2 | L3 |

| LK5 | 87 | 58 | 10 | 4 | 50 | 3 | 14 | 400 | 480 | 20 |

| LK3A | 78 | 56 | 11.4 | 4 | 45 | 3.2 | 11.5 | 200 | 75 | 25 |

| LK5A | 78 | 56 | 10 | 4 | 45 | 2 | 11.5 | 200 | 75 | 25 |

Our TK5A hollow connecting plates are precision-engineered metal joint plates specifically designed to connect two sections of TK5A hollow elevator guide rails. They ensure accurate alignment, secure fastening, and consistent load transfer, maintaining the structural integrity and smooth operation of MRL elevator systems. Tailored to the TK5A profile, these connecting plates provide reliable performance in both new installations and modernization projects, and are also known as splice plates, rail joint bars, or connecting plates.

TK5A hollow connecting plates are widely used in industrial systems where structural strength, lightweight design, and precise alignment are required. Their hollow design provides a favorable strength-to-weight ratio, making them particularly suitable for applications that involve dynamic movement or long-span connections. In automated assembly lines and material handling systems, TK5A plates are commonly used as structural links between frames, guide rails, and supporting components, helping to maintain alignment while reducing overall system inertia.

In machine tool and heavy machinery applications, TK5A hollow connecting plates are used in frame assemblies and support structures where high rigidity and vibration resistance are essential. Their hollow profile enables efficient load transfer while minimizing material usage, which helps reduce equipment weight without compromising stability. In conveyor systems, lifting platforms, and rail-guided mechanisms, TK5A plates serve as connection nodes that support repeated load cycles and maintain structural integrity over long operating periods. These characteristics make TK5A hollow connecting plates a practical choice for customized equipment and modular industrial systems where both performance and cost-efficiency are important considerations.

According to international standards: ISO7465:2007; ISO630: 2021. According to international standards, conduct comprehensive testing of raw materials based on the material certification provided by suppliers to ensure that the quality of each batch of raw materials meets the requirements.

Configure two automated guide rail production lines. The equipment must ensure that the produced items comply with or exceed customer requirements while maintaining the stability of straightness, distortion, and surface roughness

Given the stringent requirements for straightness and twist in BE grade guideways, specialized automatic straightening and twist correction equipment, along with advanced detection systems, have been implemented. The straightness is maintained within 0.5 mm, while the twist is controlled to within 30' per meter

The service concept of "customer first" asserts that, regardless of where our services are delivered—be it within the company, at the client's workplace, on the construction site, or during transportation—our primary objective remains to satisfy the client